Turbo T40-2 Centrifuge

The Turbo T40-2 is a versatile highly automated self-discharging centrifuge that clarifies and recycles fluids particulate matter entrained in the fluid down to the 1 – 10-micron range. The centrifuge has a process rate of up to 40 GPM with a solids removal rate of up to 400 pounds/shift of dry solids or sludge.

The Turbo T40-2 includes proprietary nozzles that allow solids dewatering at high speeds. Custom engineered scraper blade mechanism will be matched to the type of solids removed whether the solids compact hard like glass or whether they form a sticky paste like certain paint solids. A geared scraper drive for solids discharge ensures long term reliability. The discharged solids are dry due to a unique bowl design and high rotational speeds.

The T40-2 Centrifuge is PLC controlled to sequence the process and allow unattended operation with a digital interface and sensors for monitoring bearing wear, centrifuge speed and sludge discharge. The T40-2 can be supplied as a standalone unit, The T40-2 can be supplied as a standalone unit as well.

Or in a T40-3 three phase configuration, or combined with additional process equipment in one of our Custom Turbo Systems.

Features and Benefits:

- High Bowl Speed for Maximum Separation Efficiency

- Uses No Consumable Media

- High Speed Dewatering Reduces Solids Disposal Volumes

- Process flow rates of up to 40 GPM

- Solids Capacity providing up to ~66 lbs. of solids discharged per hour

- High Separation Efficiency with ~1,550 g’s of force

- Ability to remove particles down to the 1-micron range.

- Anodized aluminum rotors are available upon request.

-

Applications

- Metal working coolants and oils

- Optical glass grinding

- Glass Fabrication

- Ceramics and composite grinding

- Composite grinding

- Parts washing solutions

- Paint booth processes

- Gallium arsenide

- Wire Drawing

- Laundry Processes

- Insulation

- Silica Wafer cutting and grinding

- Stone cutting and grinding

- Biofuel and Oil Production

- Sludge processing and dewatering

- Wastewater clarification

-

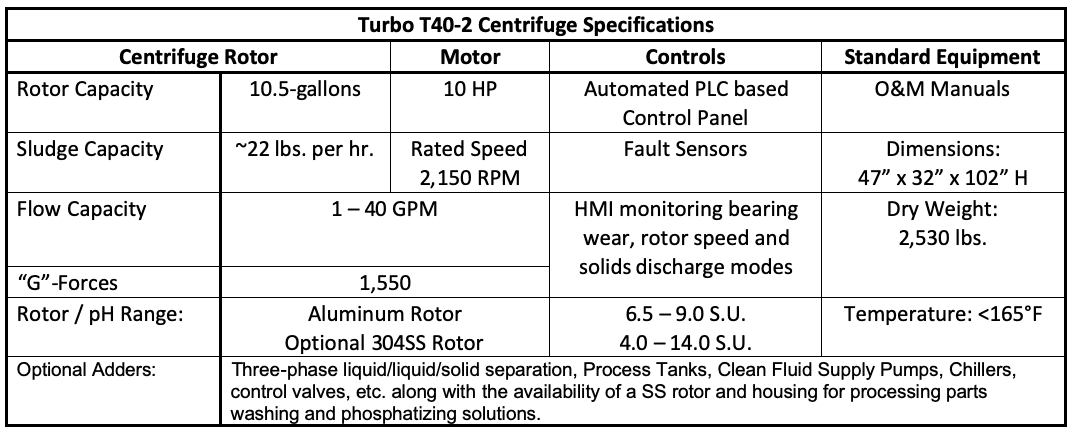

Specifications

-

Documentation