High Speed Disc Centrifuge Systems

For pristine coolant recycling and reuse

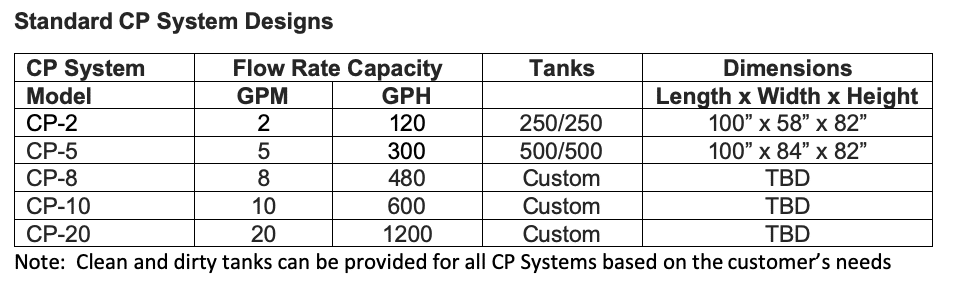

"CP" Systems

The Sanborn “CP” systems are the most efficient and effective coolant recycling systems in the industry. The heart of the CP system is the Mitsubishi self-discharging high-speed disc centrifuge.

Patriot IFR Fluid Recycling System

The Sanborn Patriot IFR Integrated Fluid Recycling System is a fully integrated system that is the best available technology metal working coolant recycling.

Pioneer IFR System

The Sanborn Pioneer IFR is a Fully Integrated Fluid Recycling Centrifuge System that is the best available technology metal working coolant recycling and fluid purification.

Benefits and Features:

-

Applications

Water-based Coolants

- Water Soluble

- Semi-synthetic

- Pure Synthetic

OilsWith the selection of the proper disc stack for oil, the CP Systems can also be configured for oil purification applications as well.

- Cutting Oils

- Hydraulic Oil

- Turbine Oil

-

Specifications

-

Documentation