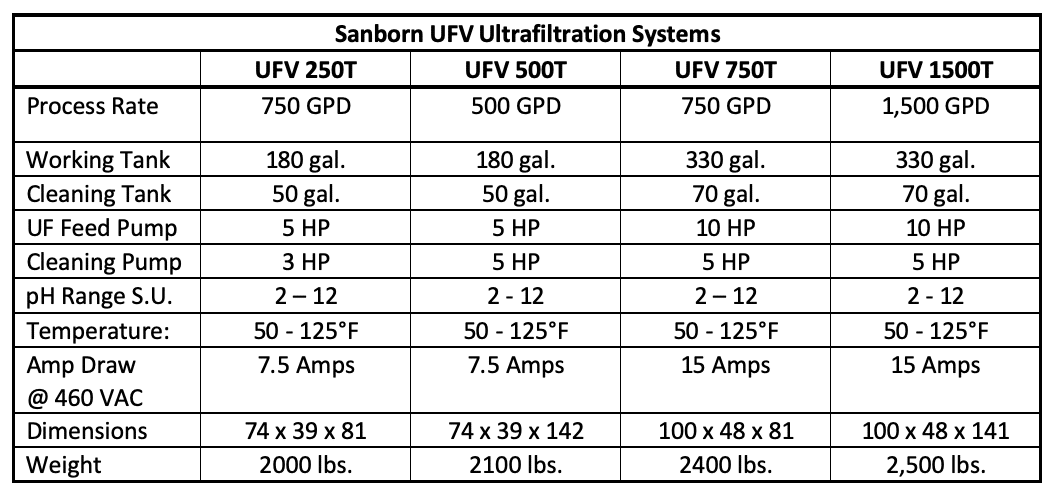

Sanborn UFV 250T- UFV 1500T Systems

Sanborn UF System Benefits and Features:

-

Applications

- Oily Wastewater Disposal

- Spent Coolants

- Vibratory Deburring Solutions

- Mop Water Disposal

- Biological Treatment Wastewater

- Air Compressor Blowdown Water

- Printing Press Wash Water

-

Specifications

-

Documentation

Download allUltrafiltration

Title Size Download UFV brochure 327.15 KB DownloadPreview UF 3000_6000 brochure 249.56 KB DownloadPreview Membrane Technology 414.95 KB DownloadPreview