Turbo T15-2 Centrifuge

-

Applications

- Metal working coolants and oils

- Optical glass grinding

- Glass Fabrication

- Ceramics grinding

- Composite grinding

- Parts washing solutions

- Paint booth processes

- Gallium arsenide

- Phosphate Solutions and Rinses

- Wire Drawing

- Laundry Processes

- Insulation

- Vibratory deburring

- Silica Wafer cutting and grinding

- Stone cutting and grinding

- Biofuel and Oil Production

- Sludge processing and dewatering

- Wastewater clarification

-

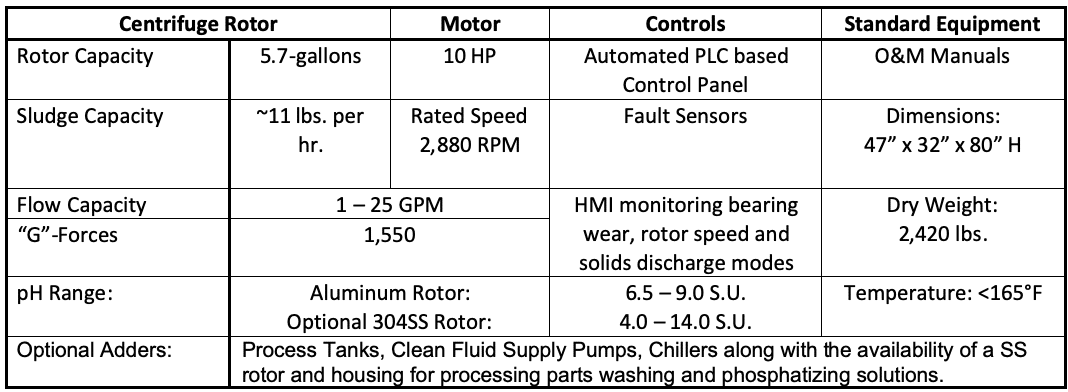

Specifications

-

Documentation