Sanborn Coolant Purifier “CP” Systems

Automatic Self-cleaning Coolant Recycling System

Features

Superior Coolant Purification to Pristine Levels

- Removes solids down to less than 5 microns (≤5 µm)

- Separates tramp fluids down to 1/4 of 1% (0.0025%)

- Reduced coolant waste by minimizing the volume of coolant removed with the tramp oil and rag layer

Simple and Efficient Operation

- Single-pass processing returns completely purified fluid

- System delivered pre-piped, pre-wired and pre-tested

Benefits

- Dramatic Direct Cost Savings

- Reduce fluid waste disposal costs up to 99%

- Reduce new fluid purchases by up to 95%

- Improved Quality and Productivity

- Cut machine down time for sump cleanouts

- Improve tool efficiency and product quality

-

Applications

Water-based Coolants

- Water Soluble

- Semi-synthetic

- Pure Synthetic

Oils – With the selection of the proper disc stack for oil, the CP Systems can also be configured for oil purification applications as well.

- Cutting Oils

- Hydraulic Oil

- Turbine Oil

-

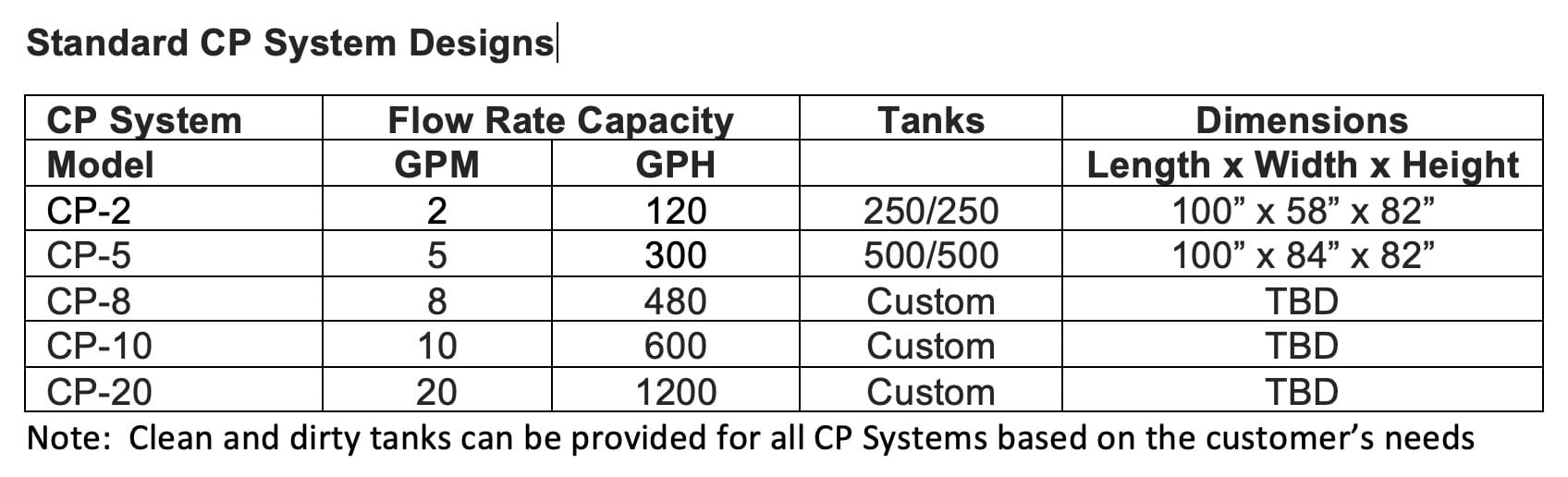

Specifications

-

Documentation